BAS Bio Active Surface

Implant success is contingent on the osseointegration process.

Successful osseointegration of bone growth around an implant is dependent on substrate properties, including surface morphology, chemical composition, and surface energy.

Dentalis’s dental implant innovation was developed and tested in three essential research levels, and has the advantages to enhance immediate and successful osseointegration.

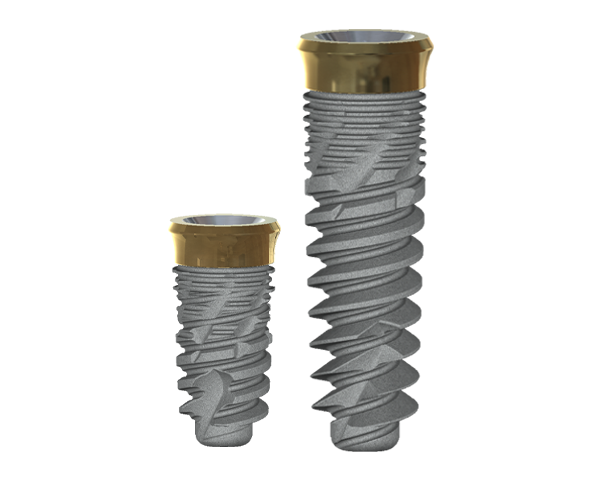

Dentalis’s implants encompass unique and advanced implant macrotopography.

Dentalis’s implant’s chemical composition is well characterized.

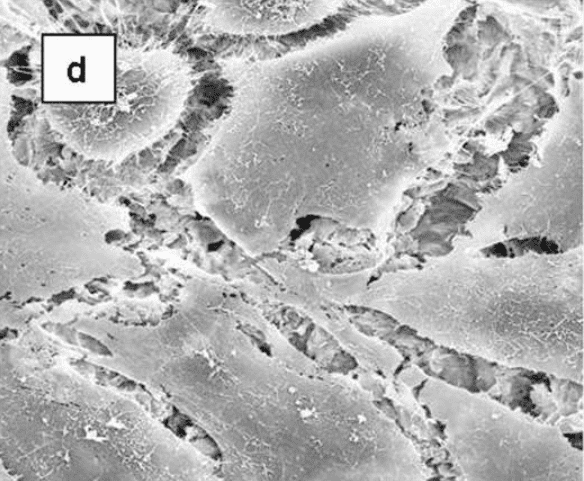

Dentalis’s implant surface was produced with specific micron-scale surface structures.

Dentalis’s implants were examined and established under in-vitro cell culture studies and in-vivo conditions. In-vitro findings established that these specific surface structures enhanced osteoblast attachment, proliferation, differentiation, and mineralization, while in-vivo studies confirmed the osteogenic effect of microstructures on Ti substrates.

BAS Bio Active Surface

Implant success is contingent on the osseointegration process.

Successful osseointegration of bone growth around an implant is dependent on substrate properties, including surface morphology, chemical composition, and surface energy.

Dentalis’s dental implant innovation was developed and tested in three essential research levels, and has the advantages to enhance immediate and successful osseointegration.

Dentalis’s implants encompass unique and advanced implant macrotopography.

Dentalis’s implant’s chemical composition is well characterized.

Dentalis’s implant surface was produced with specific micron-scale surface structures.

Dentalis’s implants were examined and established under in-vitro cell culture studies and in-vivo conditions. In-vitro findings established that these specific surface structures enhanced osteoblast attachment, proliferation, differentiation, and mineralization, while in-vivo studies confirmed the osteogenic effect of microstructures on Ti substrates.

These surfaces vastly improved bone-to-implant contact (BIC) in comparison to smooth-surfaced implants, which is correlated with improvements in removal torque strength. These observations suggest that Dentalis implants, inspired by bone biology, will improve your clinical performance and outcome.

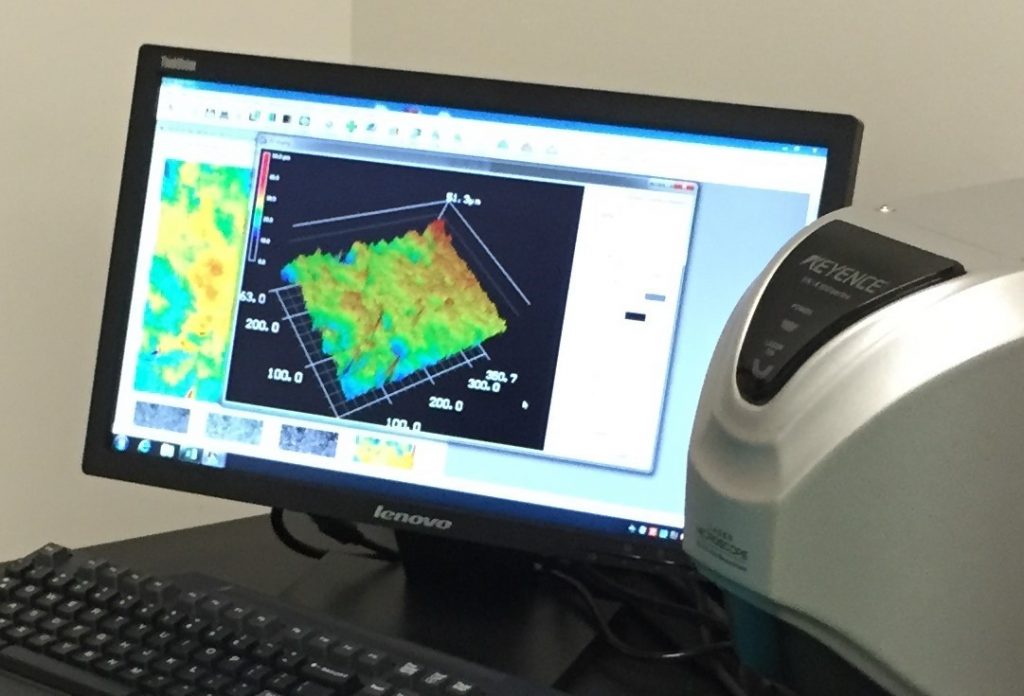

Roughness analysis

Dentalis Surface roughness is achieved by grit-blasting with a unique combination of HA particles (soluble) and different sizes of grains. This process creates optimal structural roughness on the surface and enables the incorporation of biocompatible particles, such as HA and TCP.

Determination of Ra values

Roughness was measured with an average roughness (Ra), the most commonly used parameter for describing roughness, was calculated in microns. The rough surfaces produced by grit-blasting had irregular geometries with Ra value of 3.3 μm, which is considered optimal for the osseointegration process.

Biological Response – In Vitro Study

Biological Response – In Vitro Study

Dentalis’s implant surface is the result of comprehensive scientific research examining the surface characteristics

of dental implants, in order to optimize the biological response. Research on Dentalis’ surface examines

the following properties:

Alkaline phosphatase as an early marker of differentiation –

a compound that reaches its highest concentrations as

mineralization is initiated.

Prostaglandin PGE2 is required for

osteoblast activity, and

prostaglandins mediate

cell response to the surface

structure.

Most of the transforming growth factor beta-1 secreted by MG63 cells on microstructured Ti surfaces is stored in latent form, and the amount is sensitive to surface structure.

These growth factors stimulate matrix synthesis and differentiation of osteoblasts and also inhibit osteoclasts.

In-vivo: Studies on Dentalis surface confirmed the osteogenic effect of microstructures on Ti substrates.

These surfaces improved bone-to-implant contact (BIC) in comparison to smooth-surfaced implants,

and this was correlated with 344% more stability and improved removal torque strength.

These observations suggest that Dentalis implants, inspired by bone biology,

will improve your clinical performance and outcome.

For more info about BAS ™ Surface and the Scientific Research Documentation

In vitro & In vivo experiments please:

contact your local distributor

For more info about BAS ™ Surface

For more info about BAS ™ Surface and the Scientific Research Documentation

In vitro & In vivo experiments please:

contact your local distributor

For more info about BAS ™ Surface

In-vivo: Studies on Dentalis surface confirmed the osteogenic effect of microstructures on Ti substrates.

These surfaces improved bone-to-implant contact (BIC) in comparison to smooth-surfaced implants,

and this was correlated with 344% more stability and improved removal torque strength.

These observations suggest that Dentalis implants, inspired by bone biology,

will improve your clinical performance and outcome.

For more info about BAS ™ Surface and the Scientific Research Documentation

In vitro & In vivo experiments please:

contact your local distributor

For more info about BAS ™ Surface

The combination of innovative surface technology with 344% stronger bone reduces marginal bone loss and provides for a higher BIC%, decreasing

the risk of peri-implant disease. The enhanced deep thread simplifies the insertion and allows for high primary stability.

This is the first dental implant to combine the concept of tissue-level

implants with an anti-bacterial coating on the implant neck, preventing

peri-implant disease and providing predictable results you can trust.

The combination of innovative surface technology with 344% stronger bone reduces marginal bone loss and provides for a higher BIC%, decreasing

the risk of peri-implant disease. The enhanced deep thread simplifies the insertion and allows for high primary stability.

This is the first dental implant to combine the concept of tissue-level implants with an anti-bacterial coating on the implant neck,

preventing peri-implant disease and

providing predictable results

you can trust.

The combination of innovative surface technology with 344% stronger bone reduces marginal bone loss and provides for a higher BIC%, decreasing

the risk of peri-implant disease. The enhanced deep thread simplifies the insertion and allows for high primary stability.

This is the first dental implant to combine the concept of tissue-level implants with an anti-bacterial coating on the implant neck,

preventing peri-implant disease and

providing predictable results

you can trust.